Ozone Destruction Catalyst (GTODC-GC)

GTODC-GC catalyst uses modified activated carbon as a carrier and nano-composite metal oxide as its catalytically active component. The catalyst is mainly used to purify the emission of low-medium concentration ozone. It can quickly decompose ozone into non-toxic oxygen at room temperature. The catalyst has the characteristics of relatively small bulk density, lower cost.

Technical Parameters

| Appearance | Black columnar particles | Applicable Humidity | ≤90% |

| Product size | φ(2-4mm)*(3-10mm) | Applicable Airspeed |

10,000-50,000 h-1 |

| Supports Material | Modified activated carbon | Working Temperature | ≥70 °F |

| Coating Material | Nano composite metal oxide | Purification efficiency | 95-99.9% |

| Bulk Density |

300-500 kg/m3 |

Purification Depth | 0.1 ppm |

| Specific Surface Area |

≥800 m2/g |

Service Life | 1-3 years |

| Suitable O3 Concentration | ≤500 ppm | Product Packaging | Bag or Barrel |

Advantage

1, Activated Carbon Supports

GTODC-GC uses activated carbon as a carrier and is suitable for the catalytic decomposition and removal of low-concentration ozone. It has the characteristics of high O3 removal rate, low bulk ratio and low use cost.

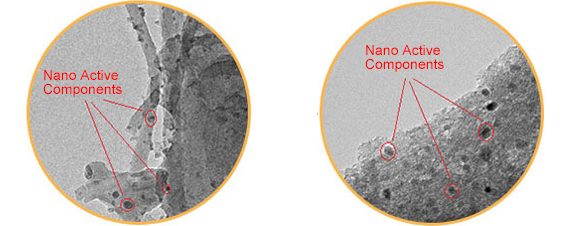

2, Firm Surface Coating

The carrier with high specific surface area is loaded with highly dispersed nano active sites, the catalytic decomposition efficiency of ozone is higher, and the ozone is instantly converted into oxygen at room temperature.

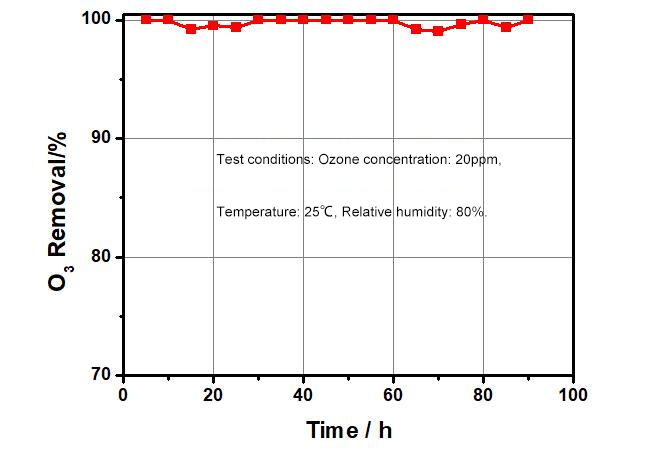

3, High Catalytic Activity

The catalyst adopts a composite multi-element catalyst system. After years of technical research and use verification, the catalyst has high catalytic activity and high stability.

4, High moisture Resistance

The coating of the ozone catalyst adopts rare earth composite oxide with high catalytic activity, which has a stable structure and can resist high humidity.

Precautions

1, Catalyst Installation

When the ozone destruction catalyst is used in the reactor, the minimum thickness of the catalyst layer is 50mm, the gas pipe does not flow shortly and the air is leaked, and all the gas passes through the catalyst layer.

2, Particle Filtration

Before the exhaust gas enters the catalyst layer, it is necessary to filter the particulate matter to avoid long-term accumulation of dust on the catalyst and cause the catalyst to fail.

3, Catalytic Temperature

The catalyst can catalyze the decomposition of ozone into oxygen at room temperature. Appropriate heating can help increase the rate of catalytic reaction. The effect is better when used at (40~80℃).

4, Restore Catalytic Activity

After the catalyst has been used for a certain period of time (for example, about one year), if the activity of the catalyst is found to be reduced due to the long-term accumulation of adsorbed moisture, the catalyst can be taken out, dried in an oven at 100°C for 6 hours or more, and then reloaded for use.

Use Scenes

1, Decomposition of ozone tail gas from ozone generator.

2, Decomposition of ozone produced by corona treatment, plasma treatment or uv-curing etc.

3, Space ozone eliminating of copier & printer, medical equipment, aircraft cabin, etc.

4, Ozone Removal in Industrial Waste Gas Emissions.